This is the main thing everyone who loves fireworks and pyrotechnics wants to learn. The base for all the kinds of fireworks is Black Powder. In this post, I will show you how I made a very good quality Black Powder to use in my fireworks.

Ingredients and main formula:

- 10% Sulfur (from agriculture store)

- 15% Charcoal (homemade from Willow wood, see here for a tutorial)

- 75% Potassium Nitrate (from agriculture store)

- Distilled water and alcohol

Usually, to prevent accidents (or minimize the effects of a possible accident), I allways make black powder is small quantities, for example, a max of 100grams each time, so, consider, for example, using the percent of the ingredients in equal weight in grams.

Tools:

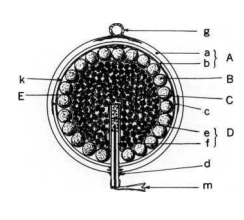

- Ball mill (with lead media or pellets).

- Mortar and pestle or any wooden tools to crush the pucks into grains

- Hydraulic press (for pressing and corning) with die (you can make one with a PVC tube and an engine piston)

Instead a ball mill, you can make a good black powder using a simple wooden mortar and pestle, but it will take a lot of time.

Preparation:

1 - Separated ingredients milling (all dry)

Sulfur + Charcoal - 1hour

Potassium Nitrate - 1hour

2 - All ingredients (a little damped (5%) with 25% water / 75% alcohol mix)

Sulfur + Charcoal + Potassium Nitrate - 2hours

Before opening your ball mill, please make sure you don't carry any static electricity within your body (put your hands in direct contact with the ground [ earth ] to discharge anything) and carefully take the powder out of the ball mill. Do not wear clothing that produces static electricity. If possible, wear goggles and gloves.

Dampen the powder a little more (I don't have a rule for this, I think you can learn by your own experience) and put it into the press die and press it using your own strenght until the press stops or starts to be extremely difficult to handle (this is also my rule, maybe there is some better calculated way to apply a more adequated force).

Take the powder buck from the press die and put it drying in the sun light.

After drying, crush the pucks into small grains. If you want to separate grains in different sizes, use an adequated sieve.

This is the finished product:

Check a small video of a sample of this powder burning.

The powder I made by the described process has a very good quality. I'm able to use it as lift powder for my shells, with a weight about 5% relative to the wheight of the shell.

Comments