I started learning vacuum forming because I desired to build a metal detector coil housing (the cover of a metal detector search coil). Basically, vacuum forming is the process of forming a plastic sheet into a usable part through vacuum between the plastic sheet and a form. Many house items we use are made by this technique.

I used the following items:

- pieces of wood to build a frame to hold the plastic sheet

- screws

- 2mm polystyrene plastic sheet

- homemade form of the piece to be replicated, made of plywood

- vacuum table (a homemade wooden box with many holes on top and a vacuum output tube)

- vacuum cleaner (mine has 1400w)

- oven (electric is better but mine was a gas oven)

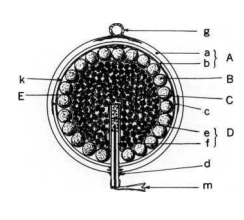

Below you can see some pictures of the parts used:

Some important tips:

- the wood form should be covered with epoxy or something that prevents the plastic from sticking to it.

- Keep the plastic inside the oven until the center of it it reaches more or lesse 150 degrees celsius or it falls (melted) about 7cm down.

- be as fast as possible between taking the plastic from the oven and putting it over the form and apply the vaccum.

This is the video of the procedure:

View a video explaining the process (in Portuguese but it has subtitles in English):

If you have doubts, wire in the comments.

Comments